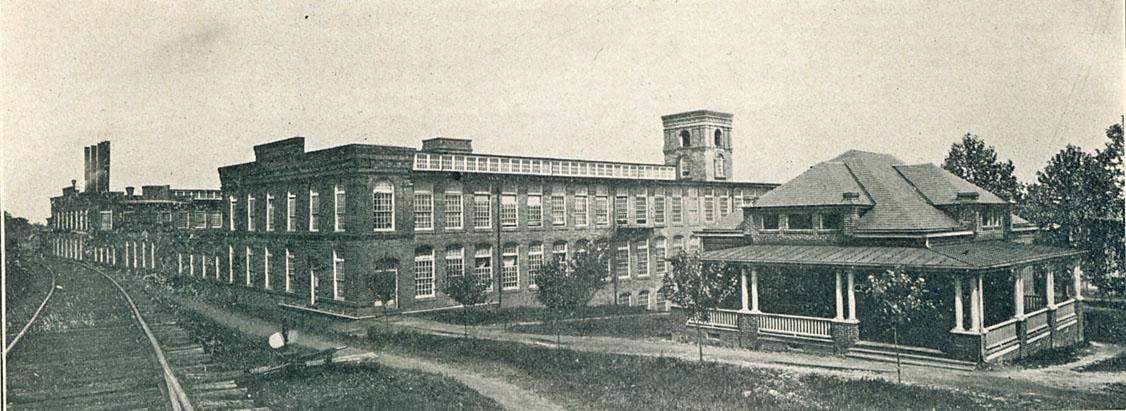

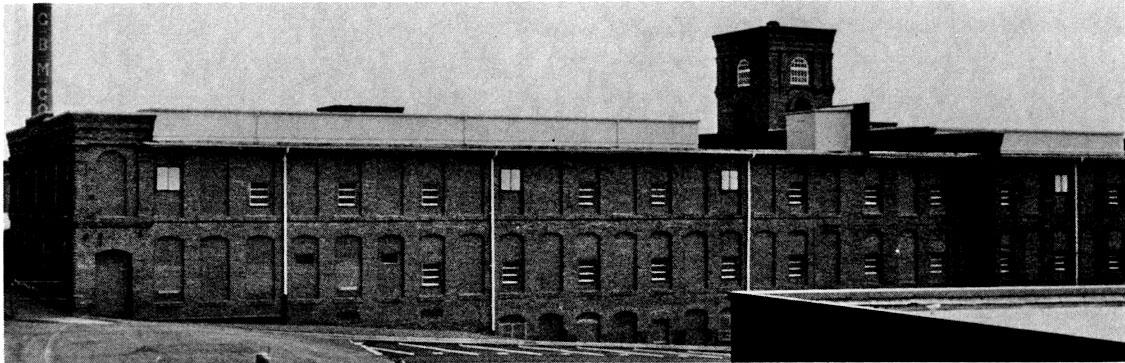

Under construction, 1901.

(Courtesy Duke Archives)

The history of Blackwell's Durham Tobacco (later American Tobacco) and the Golden Belt Manufacturing Co. are inextricably mingled. In 1887, the Golden Belt Manufacturing Co. originated in a portion of the Bull Durham Tobacco Factory (the white building at the northern extent of the American Tobacco complex) as an operation to produce the cloth bags in which the tobacco was sold. (You would, of course, roll your own cigarettes or do whatever else you liked with the tobacco.)

The tobacco company had initially contracted with dozens of independent bag-makers (primarily women working out of their homes) as well as several bag contractors (where bags were, again, sewn by hand.) The quantity of bags necessary, given the growth of the tobacco industry stimulated demand for ways to increase production. Julian Carr established Durham's first textile mill, the Durham Cotton Manufacturing company, to produce cloth. He then invested some research & development money in William H. Kerr to develop a machine that could produce bags. Kerr delivered and patented a machine in 1885 which cut and sewed the cloth, producing bags that needed only to be strung with drawstring. It reportedly "did the work of 42 women."

Kerr was hired by Carr to supervise the new mechanized "Golden Belt Bag Factory" within the Bull building. Soon, the machines were producing 10,000-15,000 bags per day, each, and the factory output increased to 2 million bags per month. By 1892, they had purchased the rights to manufacture larger bags from the Kerr Bag Manufacturing Co., and began produce multiple sizes, as well as bags for salt.

After the sale of Blackwell's Durham Tobacco to Union Tobacco in December 1898 the Golden Belt Company moved to the buildings of the former Whitted and Lyon tobacco factories on Pettigrew St., between McMannen (Mangum) and Pine (Roxboro) Sts. in February 1899. In March 1899, Blackwell's/Union was purchased by the American Tobacco Company.

In 1901, the company constructed a new factory for the Golden Belt Manufacturing company, across from Julian Carr's Durham Hosiery Mill No. 1 at Angier and Main Sts. The factory was divided into a cotton mill (Building 1) and a bag mill (Building 2.) The company also constructed 50 mill houses to the east of the facility to house families. The company employed 700 people, predominantly female.

In 1910, the bag mill building was expanded to the east by 120 feet, such that the tower that originally abutted the eastern end of the building became enclosed by the building.

The bags still needed to be strung by hand, and many residents of Durham, primarily women and children, would work from home to string and tag bags. By 1905, the company was searching for a way to mechanize this operation as well, and succeeded by 1912.

In 1906, the company built a new 2-story masonry building at the eastern edge of their property for the production of cotton hosiery - this building would be called Building 4.

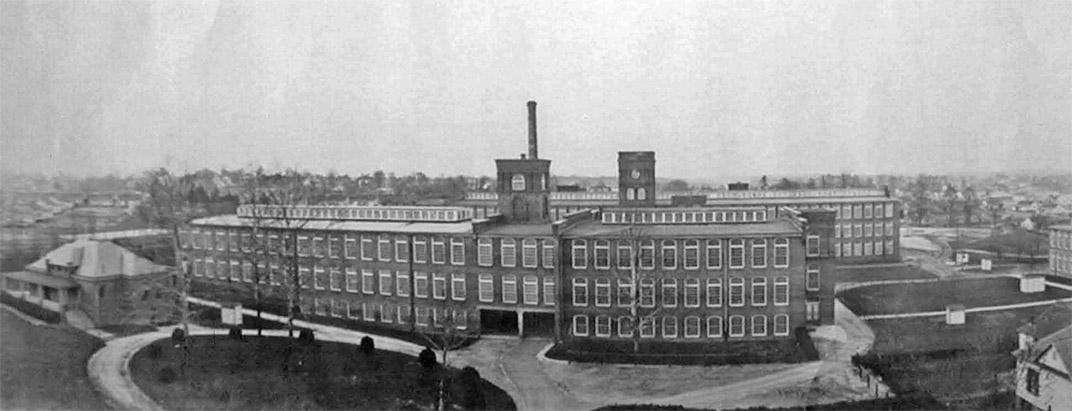

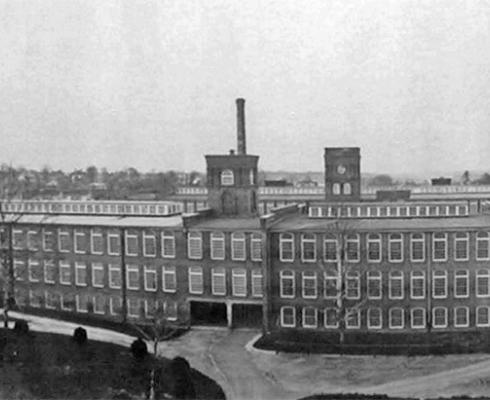

Golden Belt, 1910

It appears that Golden Belt remained a subsidiary of the American Tobacco Company after the 1911 with the Sherman Act antitrust action against the company. World War I would increase business for the factory to an all-time high.

Golden Belt, 1910s - looking north. (Likely taken from the tower of Durham Hosiery Mill No. 1.) It's easy to see the addition to Building 2 in the foreground, over and to the right of the "drive-thru" entry. A portion of Building 4 can be seen in the right background.

(Source Unknown)

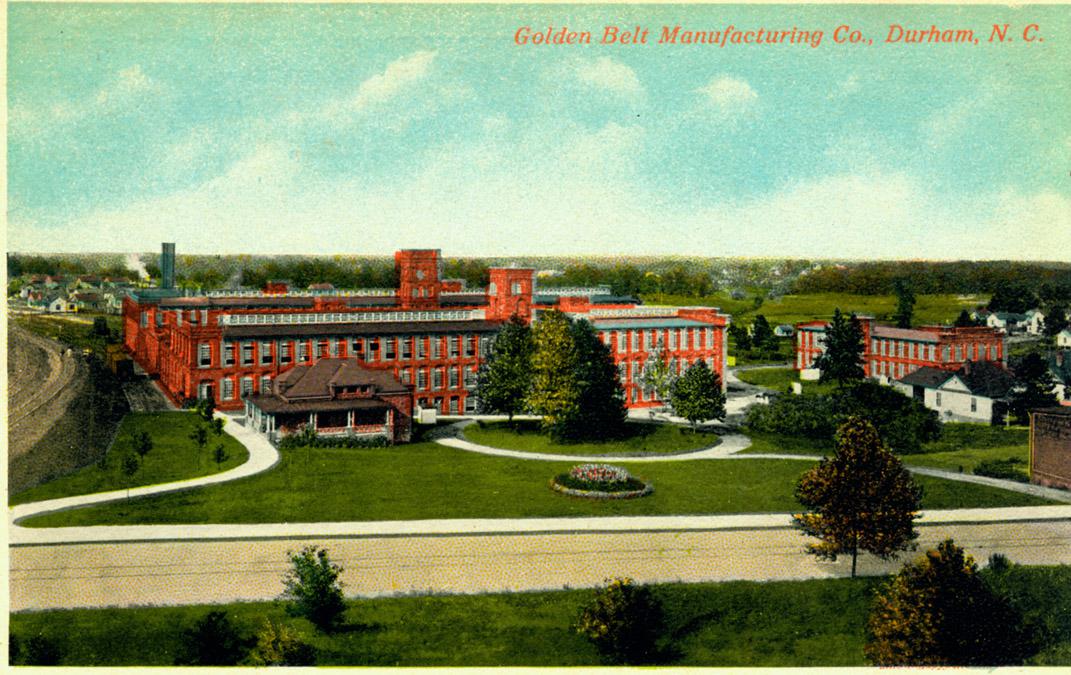

Postcard of Golden Belt from the Durham Hosiery Mill No. 1 tower, ~1910. Buildings 1, 2, their joining warehouse, and the office building (later Building 7) are visible to the left. Building 4 is separated from the others, to the right.

(Courtesy John Schelp)

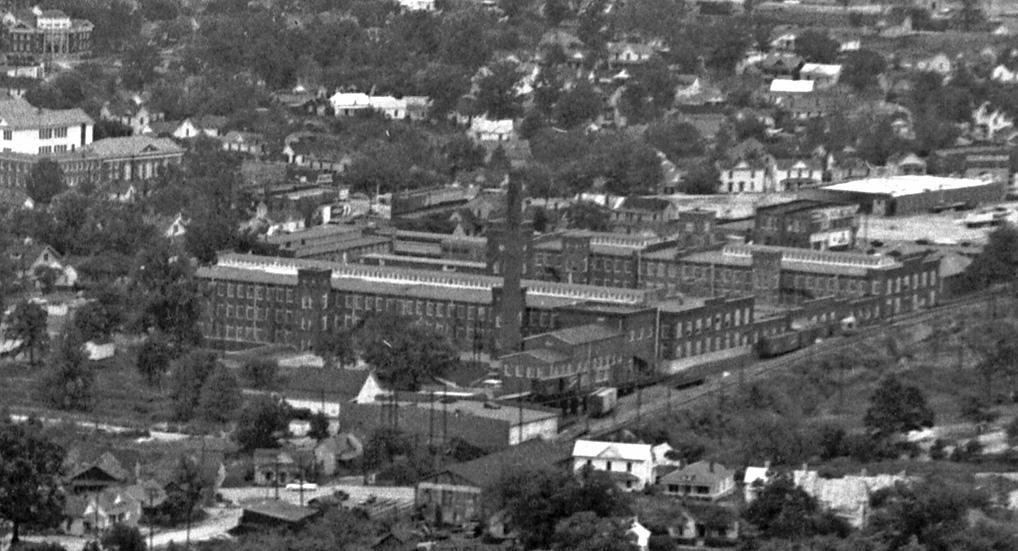

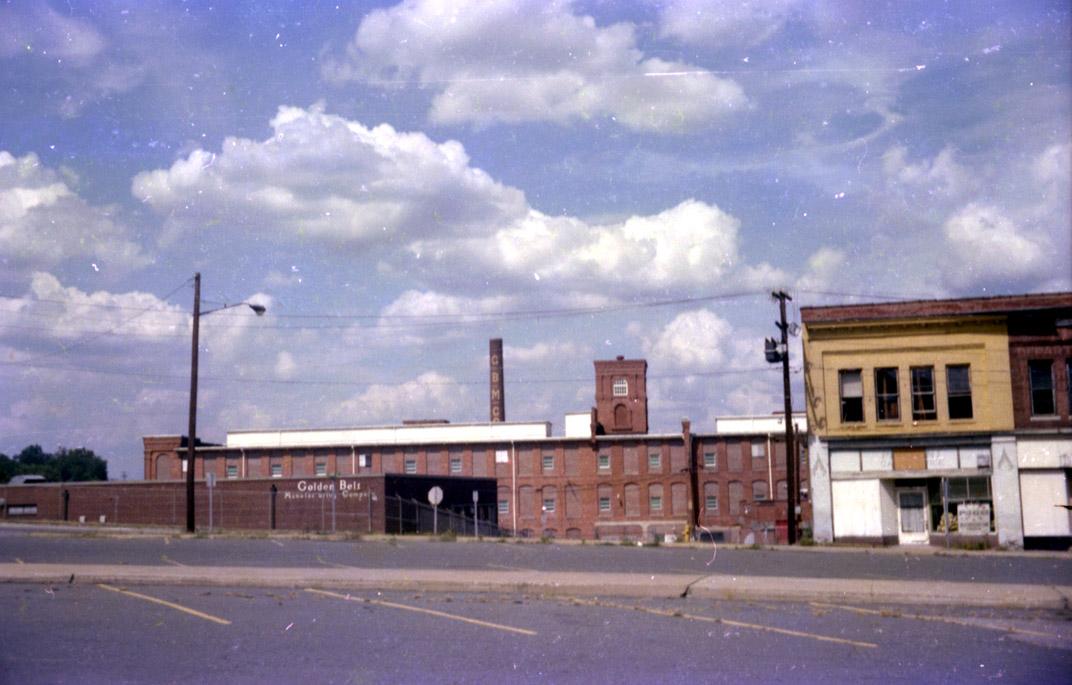

Golden Belt in the 1920s, looking northeast from the intersection of East Main and Angier Ave.

(Courtesy Duke Archives)

In 1923, Golden Belt diversified their operation again, beginning to manufacture labels and covers, boxes, and cartons for cigarette packages. By the late 1920s, cigarettes began to overtake traditional smoking tobacco. However, the depression granted a temporary reprieve, as poverty forced people to return to less expensive roll-your-own cigarettes.

(Courtesy Duke Archives)

The 1930s were an era of tumult and change for the textile industry nationally, and particularly in East Durham. The increasing importance of imported hosiery and a shift away from cotton to silk hosiery diminished the market for cotton products manufactured in Durham. By 1937, the nearby Morven Cotton Mill had been abandoned. Labor unrest accompanied the market constraint; in 1934, the United Textile Workers of America threatened a strike if working conditions were not improved – in Durham, a meeting of 3000 people was held at the Carolina Theater. Textile mills in Durham were shut down on September 1st, with the exception of the bag mill at Golden Belt, out of concern that shutting down the bag mill would shut down American Tobacco. By Sept. 6th, picket lines had shut down the bag mill and printing presses as well, but there was enough stored supply of bags to keep American Tobacco in operation. The strike ended with concessions on Sept. 25th, 1934. However, attrition continued in the local industry- by 1934 the Durham Hosiery Mill Number One, immediately to the south of Golden Belt was out of business , and by 1941, the nearby Durham Cotton Manufacturing Company was shut down.

Golden Belt, by virtue of its relationship with the American Tobacco Company – as supplier of the cotton bags for Bull Durham tobacco, remained somewhat insulated from the decline in the hosiery market, and was able to maintain its capitalization and output during the 1930s, expanding its hosiery operations and campus with the construction of Building 5 (1927) as a dye house, Building 3 (1929) as a hosiery mill, and Building 6 (1930) as a hosiery mill. The original office building was then named Building 7.

In 1938, the Golden Belt Manufacturing Company is described in the North Carolina Directory and Reference Book as employing 1000-1500 people. Despite the ability to maintain a healthy business during this era, the company recognized the market changes necessitated a shift in product output. In 1946 the company sold its hosiery operation to Hillcrest Hosiery Mills, which occupied a portion of the Golden Belt facility (within buildings 3 and 6) until the early 1950s.

The short-lived return to popularity of bagged loose-leaf tobacco during the Depression ended during the early 1940s , and the need for manufactured bags diminished with it. Golden Belt shifted towards production of paper, packaging, and labeling during the 1940s, although it maintained textile output. In 1949, the company became the first to employ gravure printing for cigarette labels. However, in 1945, the company is still noted to be a strong force in the textile industry in Durham continuing to produce bags for loose-leaf tobacco into the 1950s. The American Tobacco company prospectus from 1952, and notes from a 1953 ‘special meeting’ note that the Golden Belt Manufacturing Company

“manufactures cotton bags, principally used for the packaging of tobacco, and supplies the Company's requirements of bags for its brand BULL DURHAM ; manufactures tobacco shade cloth used to cover the fields on which Connecticut Valley shade-grown cigar wrapper tobacco is grown ; supplies a substantial portion of the requirements for such cloth of The Hatheway-Steane Corporation and also manufactures labels for tobacco and cigarette packages.”

In 1954, the company offered all of the mill houses for sale to their occupants for 10% under appraised value.

Above, Golden Belt bird's eye, looking southeast, 1950s.

(Courtesy The Herald-Sun)

The first edition of Moody’s Industrial Manual, from 1954, notes that the company was a 94.7% owned subsidiary of the American Tobacco Company at that time. The strength of the company during the 1950s can be inferred from American Tobacco Company’s ongoing efforts through the 1950s to acquire the outstanding 5.3% of Golden Belt Manufacturing Company stock that was publicly-held. This effort began in 1957, and by 1958, the American Tobacco Company owned 100% of Golden Belt stock. Co-incident with this acquisition and ongoing expansion of the company’s products and operations, the company constructed a modern office building to replace the earlier frame office building on site. This building served as the headquarters for the eventual expansion of Golden Belt’s operations to 4 additional manufacturing facilities in the US and Canada (Reidsville, NC ; Randleman, NC; Burlington, NC; Missuaga, ON.) The 1958 American Tobacco Annual Report notes that Golden Belt manufactured labels, cartons, cloth, and cloth bags, with “much of the output used by [American Tobacco] and the balance sold to others.”

Above, Golden Belt from the air in 1959. The Durham Hosiery Mills buildings are to the left and down (southwest.) This picture also shows how the path of Elizabeth St. was significantly further to the west before it was realigned to link with Fayetteville St. in the 1960s.

A view of the boiler plant and the north side of the complex, 1959 - looking southeast from where the beltline railroad tracks cross Liberty St.

(Courtesy Bob Blake)

Late 1950s picture of Buildings 2,3,4, and 6 - looking east from the Golden Belt parking lot.

(Courtesy The Herald-Sun)

By the 1960s, Golden Belt again diversified - this time into plastics production. In 1965, the company installed injection plastic molding machinery. The American Tobacco Annual Report notes that Golden Belt “experienced a significant increase in operating profits on a strong sales gain.” Plastics production was increased by 50% in 1967 to meet greater demand for plastic products. This growth necessitated a $2-million, 34,000-square-foot addition to Golden Belt's Durham factory during 1966-68. This project, which included the installation of all-new equipment, enabled the company to diversify its textile production, adding single and plied yarn for sale to knitters and weavers. This operations expansion included the 1968 addition to the company’s main office building. That same year, Golden Belt experimented with production of molded plastic filters for cigarettes and adding synthetic orange flavoring to tobacco bags.

Below, the facility in the late 1970s.

And another view from across E. Main St., 1981.

(Courtesy Robby Delius)

An aerial view from a similar timeframe.

The company continued to manufacture cigarette packaging into the 1990s. Business continued to decrease, however, and the loss of Phillip-Morris' business in 1992 halved revenue. In 1995, Brown and Williamson acquired American Tobacco. An antitrust judgment evidently forced them to sell off several brands. Curiously, this may have led to them rejecting an offer from an employee to purchase the entire plant for $16 million and instead breaking up the company.

In 1996 Brown and Williamson Tobacco Co., the owner, failed to attract a buyer for the buildings and donated the facility to the Durham Housing Authority. One building was renovated by the housing authority as the Golden Belt business incubator, and I believe several other tenants leased space in the building. It appears that Julio Cordoba of Raleigh purchased the northern portion of the facility in 2002 to create the East Village Corporate Center, which would provide space for small business tenants. This entity received $36,000 in incentives to create jobs at the site, and still occupies this building.

In 2004, the DVI subsidiary of the Durham Housing Authority put the southern portion of the complex on the market. It was sold to Andy Rothschild of Scientific Properties in October 2006, for $2.6 million. Andy has proposed a mixed use redevelopment of the complex, which would include artist studios, apartments, retail, and office space - from a $12.5 million investment in the project.

Note that this does not include the northern buildings, still owned by Cordoba. Elizabeth Street would be just to the left of the beltline railroad tracks, which have been the subject of ongoing negotiations between the city and Norfolk-Southern for purchase and conversion to a rail-trail.

Below, a view of the complex from East Main St., similar to the above historical photos, 2007 ("building 2" on the site plan.)

Below, a view from Morning Glory of the east end of the complex (building 6) - 2007.

Below, "building 2" in the first 2007 picture, above, seen from the north side, looking southwest, 2007.

Below, a renovated building ("building 4")at Golden Belt on the east side of the complex, looking southeast.

Below, the East Village complex on the north side of the parking lot, not part of Rothschild's purchase or redevelopment, 2007.

Should incentives go through, as expected, the project is expected to begin this summer. Incentives for this project are, in my mind, a no-brainer; Golden Belt will be the centerpiece of HOPE VI-driven revitalization of Edgemont/Morning Glory and the east side of downtown. I believe it will have a strong positive impact on the surrounding neighborhood - if we can keep DOT from over-widening Alston Avenue, the County from demolishing the entire 300 block of East Main, and NIS from demolishing dozens of houses - all before the positive effects of investment can arrive.

Update: Golden Belt began renovation in earnest in mid-2007. In July 2008, the complex opened for business with 35 artist studios and 37 apartments, along with office space for the city of Durham.

Golden Belt, looking northeast, 09.28.08 (Photo by Gary Kueber)

Building Four, 11.13.13 (Photo by Gary Kueber)

(Photo by Gary Kueber)

Add new comment

Log in or register to post comments.